If you’re a retailer, you probably know that there is a wide variety of packaging options available to ship your customer orders. In addition to traditional options like boxes, poly mailers are quickly becoming the preferred choice of many shippers. With perks like low supply costs and quick assembly, poly mailers sound like a rock star solution, but how can you be sure they are right for you? Looking at some very specific scenarios can help determine when to use a poly mailer.

Scenario 1 - When you need assembly to be fast and efficient

No one wants to waste time packaging shipments - and poly mailers are a great option when you want to streamline your shipping process. Unlike boxes, which require assembly, tape, and internal elements like foam core, poly mailers are ready to use right off the shelf. Once you select which mailer style to use, all you need to do is insert the item, seal the mailer, and add the shipping label.

An added bonus is that poly mailers can streamline and simplify storage for your packing materials. They take up less space, which means you can store more of them in your warehouse. If you have limited storage space, and a smaller team to manage your shipping, these efficiencies can be a lifesaver.

Scenario 2 - When you want to keep shipping supplies costs low

Keeping shipping supplies on hand can get pricey, especially if you need to order custom-sized items like boxes for packaging. If you’re looking to save money on supplies, poly mailers are a great option. They are typically less expensive than boxes - on average they cost $0.25 a mailer compared to $1.25 for a box of a similar size. For extra protection, you can find bubble mailers, which have padding built in. Bubble mailers don't require additional packing materials like Styrofoam peanuts, so you're saving some money there. All types of mailers are able to be purchased in bulk, which helps with cost savings.

Another perk you get with poly mailers is that if your supplies unexpectedly run low they are easy to find at places like office supply or grocery stores. While it’s always best to keep an appropriate amount of packaging on hand, if you’re in a pinch, finding more won’t be difficult or break the bank. These factors all add up to significant savings over time, especially if you ship a moderate to high volume of products.

Scenario 3 - If you want to avoid high DIM weight charges

As many retailers know, small package carriers use dimensional weight (DIM weight) pricing to calculate shipping costs. Carriers do not like to waste space on their trucks, so shipping large, lightweight packages is a no-no. These bulky packages will cost you, and this is a significant expense that quickly adds up for many retailers. A smart way to offset these high costs is to make sure you are minimizing wasted space, and that’s where poly mailers come in.

Poly mailers are small, thin, and flexible - they can be folded and resized to best fit the product inside. These small, dense packages allow for greater efficiency for the carrier, and will cost you less in the long run.

Scenario 4 - When you want a specific type of protection

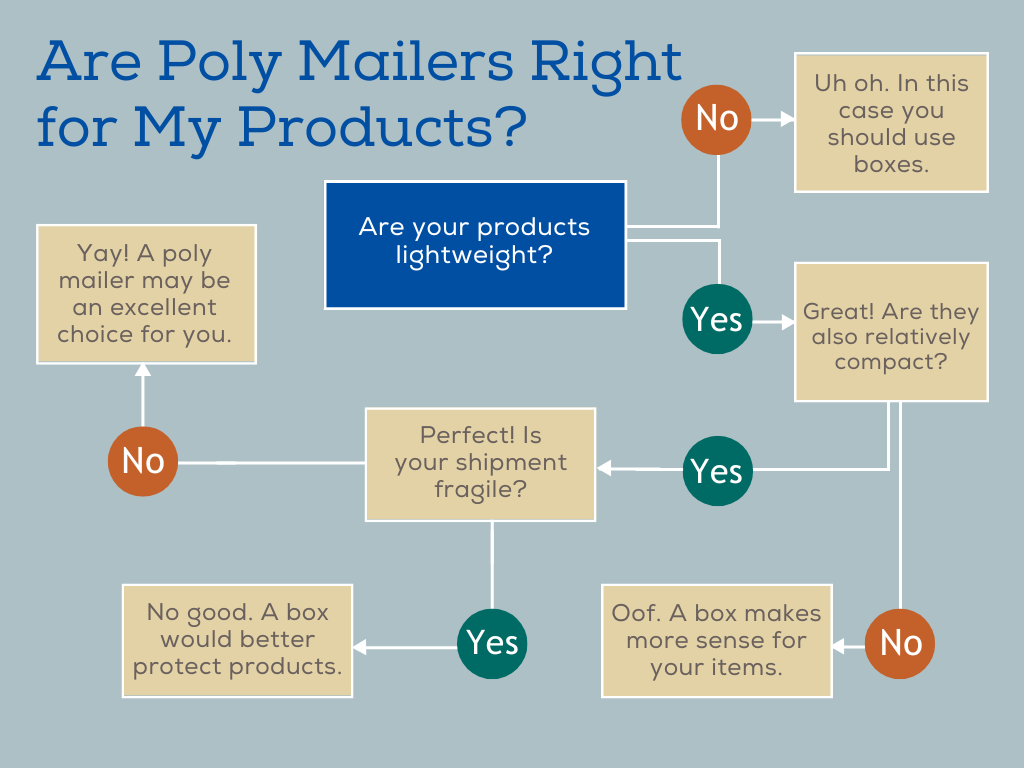

Poly mailers are economical and convenient, but they are not suitable for all types of products. If you’re shipping fragile items, or those too large and heavy to fit securely in a mailer, you may need to use a different type of packaging.

Poly mailers are ideal for soft goods like clothing, bedding, purses and backpacks, and some accessories like belts or scarves and knit hats. Padded mailers that offer additional lightweight protection are great for books and printed materials, DVD and blu ray discs, some jewelry, cosmetics and skincare items, and select types of home goods like flatware.

If you’re shipping the right items that are not easily damaged, poly mailers can offer excellent protection. They are made from durable materials that can withstand normal handling during shipping. They are tear resistant, and also offer dirt and weather protection that is ideal for small items going to residential mailboxes.

Scenario 5 - When eco-friendly shipping is important

Finally, if you’re committed to eco-friendly shipping practices, poly mailers can be a great option for your business. They are often made from fully compostable or recyclable materials. You can often drop off poly mailers at the same places that would recycle plastic bags and containers. Poly mailers are also generally lightweight compared to boxes, which is more energy efficient for carriers.

Most significantly, poly mailers are often completely reusable. Many options have a secondary adhesive strip that allows them to be used for return shipping of orders, or even reused by the consumer for other shipping purposes. Even those without a second strip can be folded over at the opening and secured with tape - their durable material can withstand multiple journeys through a shipping network. These factors combined make poly mailers a great choice for retailers who want to reduce their environmental impact by reducing packaging waste.

Poly mailers are a great option for retailers - when it’s the right product

Poly mailers are a versatile and cost-effective option for small package shipping, and work very well for many ecommerce retailers. They can help streamline your order fulfillment process, enforce brand awareness, and help avoid high DIM weight costs. You may be able to save even more on your small package shipping if you belong to an association or chamber that works with PartnerShip. Contact our team to find out what options are available to your business.