How to Save on Shipping While Reducing Packaging Waste

04/11/2022 — Jen Deming

We love shopping online. Nothing beats the convenience of delivery, variety of product options, and satisfaction of adding things to a virtual cart and clicking ‘buy now’. Unfortunately, the perks of ecommerce do have a flipside - the environmental impact of shipment packaging waste. Ecommerce shipping actually has about four times as many touch-points as regular retail. This means more packing and unpacking individual orders to customers – leading to even more packaging waste. Savvy e-retailers are minimizing their environmental impact by using eco-friendly shipping tactics and by using less wasteful packaging procedures. Even better, reducing your shipment packaging waste is a sustainable practice that is both eco-friendly and a smart way to lower shipping costs, through these three easy tips.

Tip 1: Reduce the amount of your packaging

Tip 1: Reduce the amount of your packaging

If you’re a shrewd retailer, you know that your choice of packaging can protect your product, prevent damage, and enhance the value of your brand through the unboxing experience. But not every product ordered online needs to be shipped within layer upon layer of branded boxes and plastic packaging. Taking a “less is more” approach can help balance both cost and structural integrity, in addition to lowering packaging waste.

When you’re considering what types of shipment packaging to use, retailers have a ton of options. Packaging materials include paper, plastic, or chipboard boxes, foil or poly envelopes, bubble mailers, jute, vinyl, or cotton bags, and many other options. Dunnage, or the internal “protective” material inside the shipment can be Styrofoam, cardboard, kraft paper, soft or rigid plastics, and bubble wrap. Each option has its own cost, key benefit, and impact on the environment. Research what types of shipment packaging make the most sense to adequately protect your product, and then eliminate the use of unnecessary extra materials. Always keep in mind that you can reduce your initial cost and environmental impact by choosing simple, but effective shipment packaging that makes sense for your product and consumer.

Tip 2: Reduce the weight and dimensions of your shipment

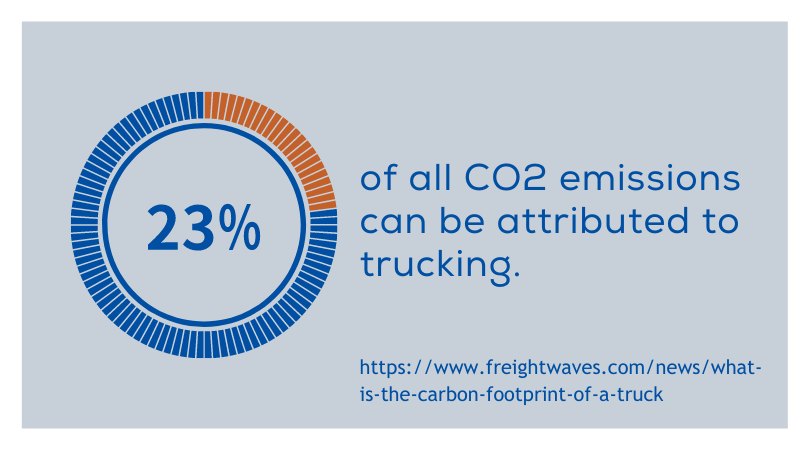

It’s clear that wasteful packaging procedures can drive up initial costs, but keep in mind that any unnecessary materials can also affect your shipment rates due to weight and density. Your parcel rate is determined in large part by region, distance traveled, and weight. Heavy shipments put more strain on trucks and utilize more fuel when hauling loads. As a result, carriers will charge you more for added weight.

Another factor that can affect your shipment cost is dimensional weight. DIM weight pricing is used by carriers to offset the cost of moving large and bulky shipments in their network. This pricing strategy focuses not just on the actual weight, but also the amount of space your shipment takes up. Your DIM weight is determined by the dimensions of your shipment. If the calculated DIM weight is higher than the actual weight, your shipment will be rated on that.

Elaborate packaging with multiple components inside runs the risk of wasted interior space, so making sure that you right-size your package is important. Ensure that there is no empty space within your shipping box after the product and protective materials are added in. Reducing wasted space within your shipment can lower your final bill, and greatly reduces packaging waste that can be harmful to the environment.

Tip 3: Encourage your customer to use your packaging for returns

With more people preferring to shop online, the need for convenient returns options increases. Being intentional in how you approach your returns can help lower reverse logistics costs while remaining environmentally conscious.

Every online shopper knows that preparing to ship a return can be a pain. No one loves rummaging through a garage of broken-down boxes hoping to find one adequate for use. It’s not as simple as grabbing an empty box - the package must be structurally sound and free of pre-existing labels to avoid hiccups on the road.

Do your customers (and yourself) a favor, and make this process even easier by utilizing return-ready packaging for your orders, including resealable boxes, envelopes, and mailers. Include pre-printed shipping labels with return addresses and packing slips to help make the process even simpler. By providing return-ready packaging, you’re ensuring that the package is right-sized for pre-paid shipping labels and services. As a retailer, you’re taking steps to avoid possible damages or loss by providing packaging options that securely protect your product while in transit.

In short, by providing return-ready packaging, you’re taking back control of return shipments by managing several variables that may lead to costly surprises and packaging waste.

Reducing packaging waste benefits everyone

Retailers have a unique opportunity to improve the eco-footprint left by their businesses. Environmentally friendly shipping practices can help lower emissions on the road, reduce packaging waste headed for landfills, and lower costs. To further improve your environmental impact, consider working with a sustainably minded shipping provider, like PartnerShip. We elect to work with carriers that prioritize energy efficiency in trucks and facilities, minimize air-pollution, and offer transparency through data about fuel usage and impact. Optimizing your packaging is a smart place to start – learn how with our downloadable, free white paper.