Here at PartnerShip, we truly value our team members and put a strong emphasis on connectivity between staff. During the past year, working remotely has made it more challenging to maintain our culture, but that hasn't changed our commitment to supporting each other. We recently brought on six new staff members and while we get to know them, we thought you'd also like to help us welcome them to the team! Learn more about these new faces of PartnerShip below.

What do you like to do in your free time?

I collect tropical houseplants and have a vegetable garden. I also spend a lot of time making macrame art, sketching, reading and going hiking.

Do you have any nicknames?

All of my friends call me Bea.

What is your favorite 90s Jam?

Say It Ain't So - Weezer

What's the best vacation you've been on?

Every few months my partner and I drive to Asheville, NC to go hiking. It’s my favorite place, so it’s always the best to get away in the mountains.

What do your colleagues say is your best attribute?My favorite coworker from one of my past jobs says I am great at talking to people and meeting them where they are at.

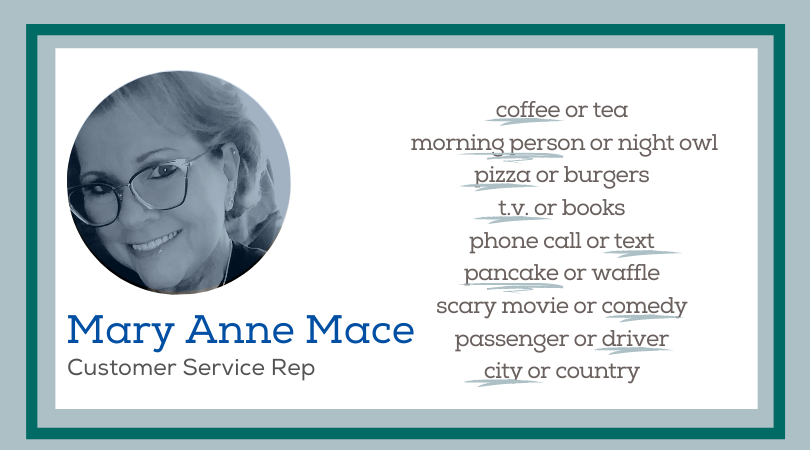

What do you like to do in your free time?

Walk the park with my dog Bella and visit with my grandbabies.

Do you have any nicknames?

Yes, Grace.

What is your favorite 90s Jam?

Don't have one.

What's the best vacation you've been on?

Visiting my grandbabies in West Virginia.

What do your colleagues say is your best attribute?My outgoing personality!

What do you like to do in your free time?

I spend my free time having fun with my two daughters. I also enjoy collecting really old books and doing activities outside around the bay.

Do you have any nicknames?

Rae Rae

What is your favorite 90s Jam?

Alice in Chains – Man in the Box

What's the best vacation you've been on?

Best Scenery: Lake Louise (Banff National Park). Most Fun: Italy/New Orleans/Key West

What do your colleagues say is your best attribute?My helpful attitude.

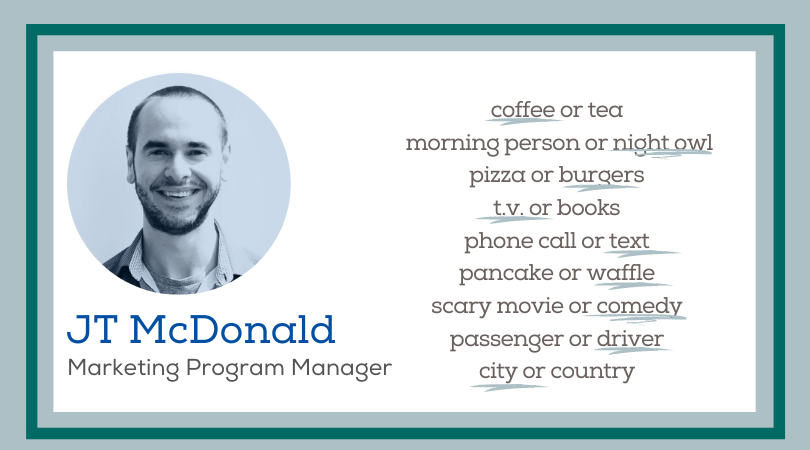

What do you like to do in your free time?

I race Motocross, play guitar, play with my dogs Ryder & Sophie and try out new recipes

Do you have any nicknames?

JT is a nickname that was given to me when I was about a week old. My full name is John Thomas but my Dad’s name is also John. A week in my parents realized that calling me John would be confusing and John Thomas was too long so JT was what they settled on and I’ve gone by that since.

What is your favorite 90s Jam?

One Headlight - The Wallflowers

What's the best vacation you've been on?

Waikoloa Hawaii. Such a beautiful place with great beaches, volcanos to explore and amazing food.

What do your colleagues say is your best attribute?My ability to wear many hats and take on any project.

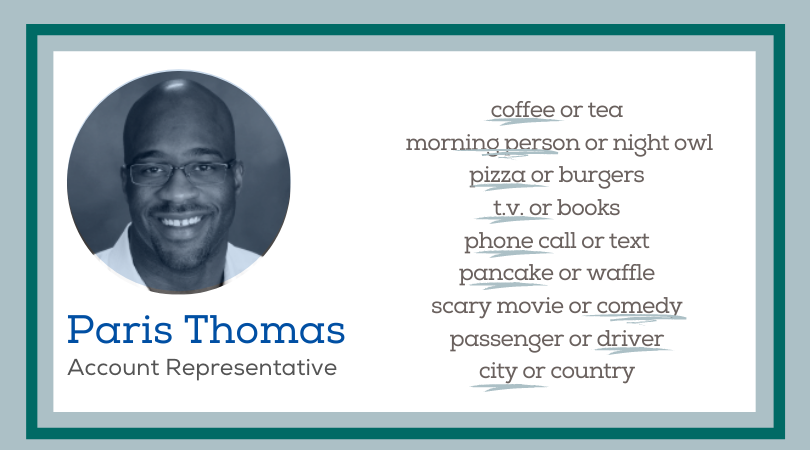

What do you like to do in your free time?

I like to catch up on my reading in my free time.

Do you have any nicknames?

No nicknames.

What is your favorite 90s Jam?

Return of the Mack - Mark Morrison

What's the best vacation you've been on?

Dominican Republic - when I was married.

What do your colleagues say is your best attribute?I'm very aware of my surroundings and I'm always willing to learn.

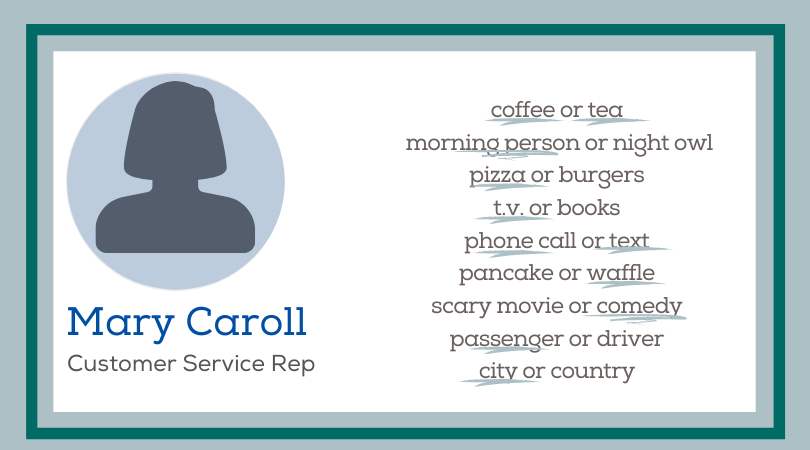

What do you like to do in your free time?

Spend time with my children.

Do you have any nicknames?

No.

What is your favorite 90s Jam?

Wonderwall - Oasis

What's the best vacation you've been on?

Universal Studios.

What do your colleagues say is your best attribute?Kindness.